How to Print T-Shirt Designs & T-Shirt Printing Types for Print on Demand Business

The T-shirt printing industry, despite appearing as a simple market, actually entails a whole process that must be successfully executed to achieve the best results. At least, The Global Custom T-shirt Printing market size was valued at USD 5582.29 million in 2021 and is expected to expand at a CAGR of 9.67% during the forecast period, reaching USD 9711.35 million by 2027 (Precision Reports, 2022).

This indicates that this market segment is constantly growing and yields very good sales.

For this reason, as a team that loves everything creative like designing and printing our own t-shirts, we’ve definitely had our share of trial and error when it comes to getting the best results. So if you’re looking for the most valuable tips on how to print a t-shirt design with better results, here are a few things that we have learned over the years.

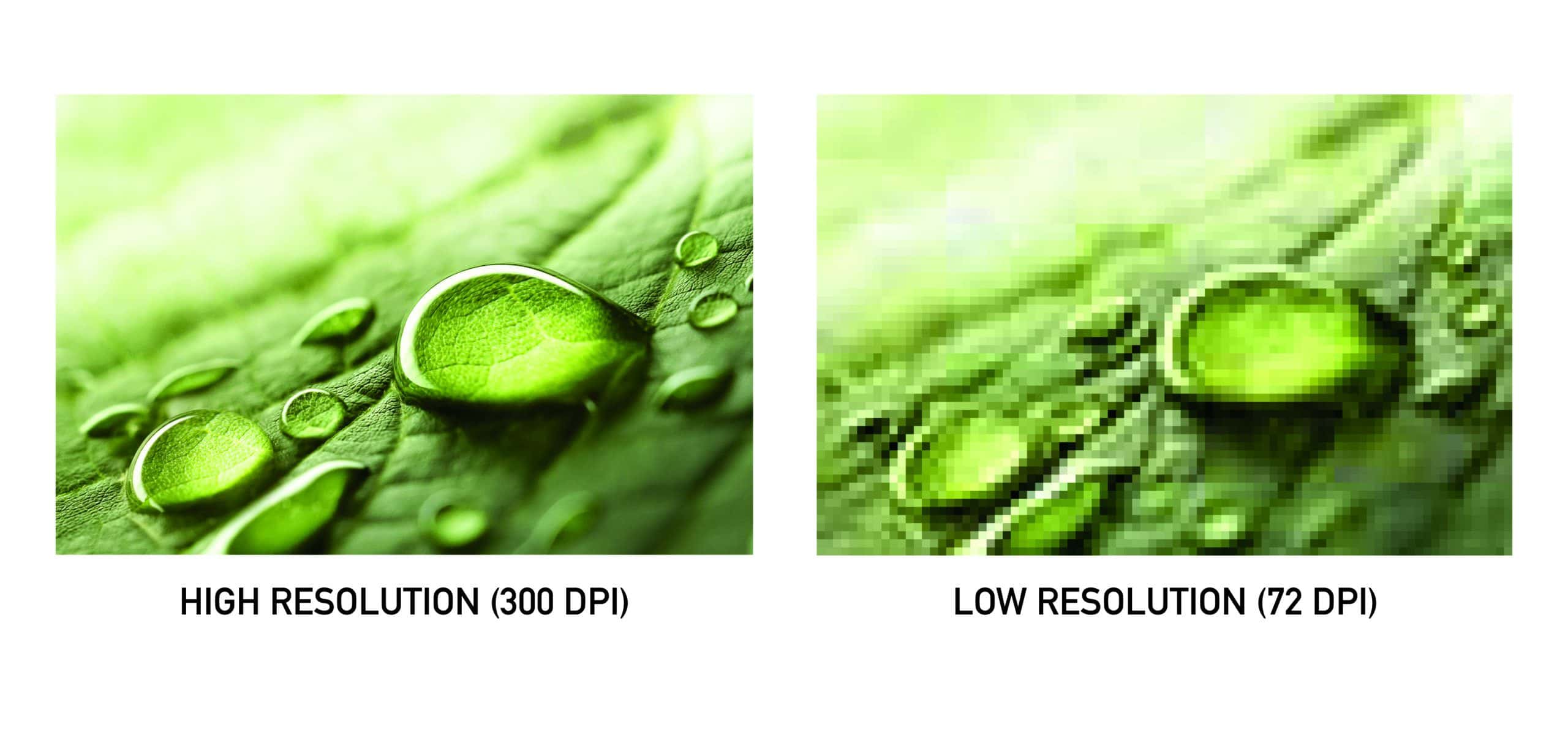

Make Sure Your Design is High Quality

This may seem like a no-brainer, but it’s essential to make sure your design has the proper resolution to print well. Resolution is measured in ppi (pixels per inch) when talking about images on a screen or dpi (dots per inch) when talking about printed images. By proper resolution for printing, we mean working with files set between 180-300 dpi, but keep in mind that the higher the dpi, the heavier the file will be.

In my case, searching for T-shirts in the market that fit personal taste is complicated. For a few years now, I’ve started to have my T-shirts printed with designs of my favorite bands, characters from series, phrases, among others.

This has led me to want to stay constantly updated about the trends used in these processes, as understanding how it’s done would help me choose better designs, graphics, colors, and typography so that, at the time of printing, they don’t come out of poor quality.

Even though the T-shirts are for personal use, it’s important that they’re good, because for me, having a T-shirt with a high-definition design and good quality is fundamental because I invest time and money in this.

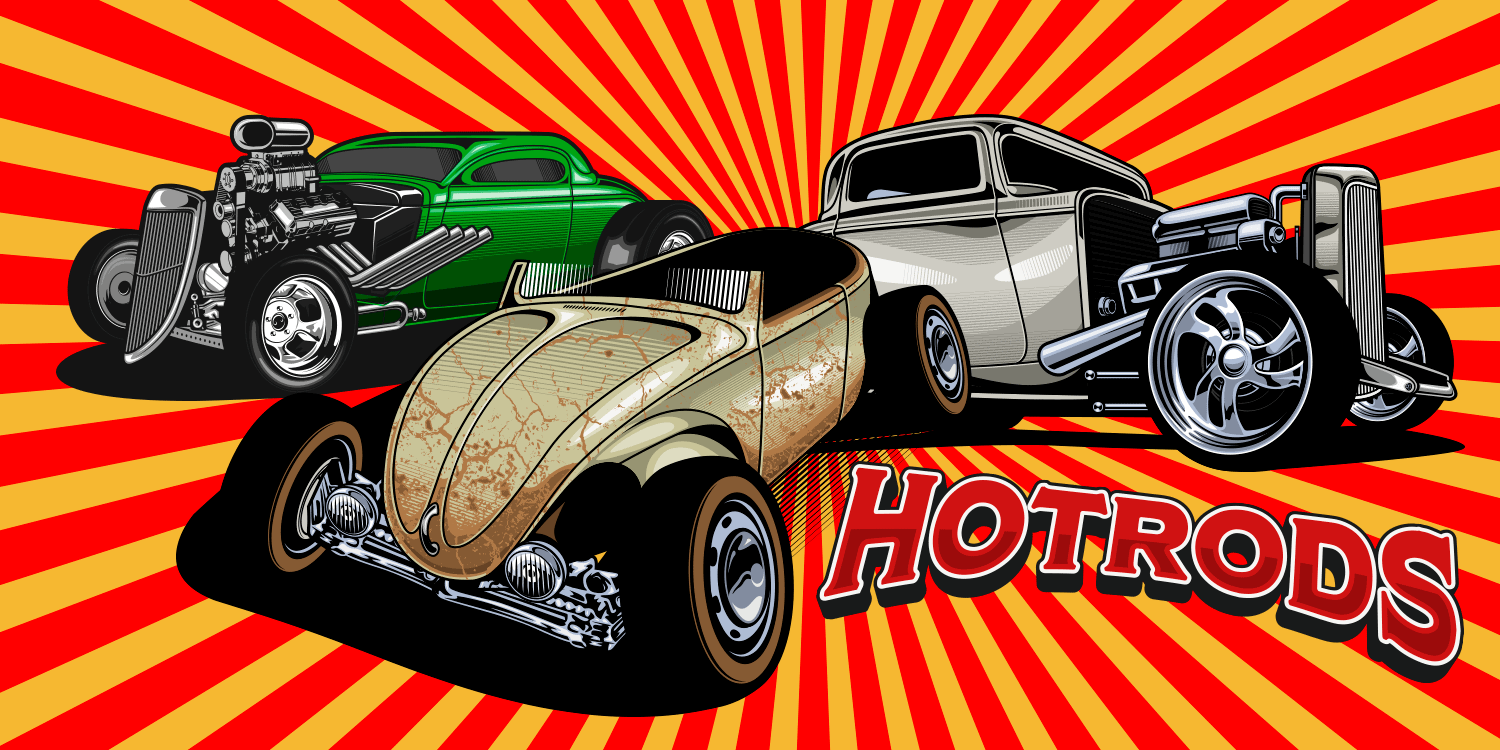

So if you’re completely lost on what kind of designs to use, don’t worry! We have a huge selection of cool t-shirt designs that already have the best quality so that you can use and pass them directly to your printer, as these were made with the print process in mind.

Use the Right Kind of Transfer Paper

Not all transfer papers are created equal, and using the right kind is an essential part of getting great results when printing your design onto a t-shirt. We recommend two: Inkjet transfer paper is the most common and popular type of paper for cotton and cotton blend fabrics. On the other hand, sublimation paper is a perfect solution to use for polyester, synthetic fabrics and polyester mix blends.

In any case, it’s best to ask your printer for their recommendations on which type of paper will work best for your design. And remember, always follow any specific directions provided with the transfer paper you use.

It’s always a good idea to test print your design on a scrap piece of fabric before printing it on the t-shirt you want to customize. Doing this will allow you to check how your design looks once applied, making sure it’s exactly what you had in mind or fixing any mistakes before they’re made on the actual t-shirt.

This is if you want to see how your final design would look on the fabric. But if you just want to get an idea of the size, position or color, then we recommend you to use our huge collection of t-shirt mockups, this will be your best tool to have a preview of your design, plus you can use them as many times as you want.

By the way, we have many more mockup packages for everything you can imagine; they will come in handy!

Follow the Care Instructions

Once you’ve printed your design onto the t-shirt, it’s essential to follow any after-care instructions that are provided by the transfer paper manufacturer, but these are our favorite tips:

- For washing: turn the tee inside out to prevent it from rubbing against other fabrics.

- For drying: hang them away from direct contact with sunlight.

- For ironing: simply don’t! Heat is an all-around enemy to your printed tee, but if you absolutely must, use the lowest setting and iron the garment inside out.

These precautions will help prevent your printed designs from getting damaged or worn out too quickly from regular use, so you can enjoy your custom printed t-shirt for as long as possible!

Why is Printing Custom T-Shirts Better?

The importance of creating your t-shirts from scratch rather than buying them pre-made from a store lies in a company’s need to seek authenticity and originality to set itself apart from its peers. Therefore, it is important that the designs are unique and represent the values and ideals of the brand or in other scenarios, the values of the individuals that wear the t-shirts.

However, it is not as simple as picking a design, and placing it on any garment: there are several printing methods, each one with different pros and cons, and the method you choose will determine everything from the material you should use for your custom T-Shirts, all the way down to the life expectancy of the printed design on the garment.

For example, for Christmas at my brother’s company, he gave his customers a Christmas T-Shirt as a bonus with their purchases. However, he didn’t know how the process worked, so he decided to turn to a company that guided him through it. There, they emphasized the importance of coherence in both the design and the material of the T-Shirt, of which he had no knowledge.

For him, printing T-shirts was simply choosing a design and buying any plain-colored T-shirt, but he was mistaken. Not all garments use the same process, and specific techniques are recommended for each one.

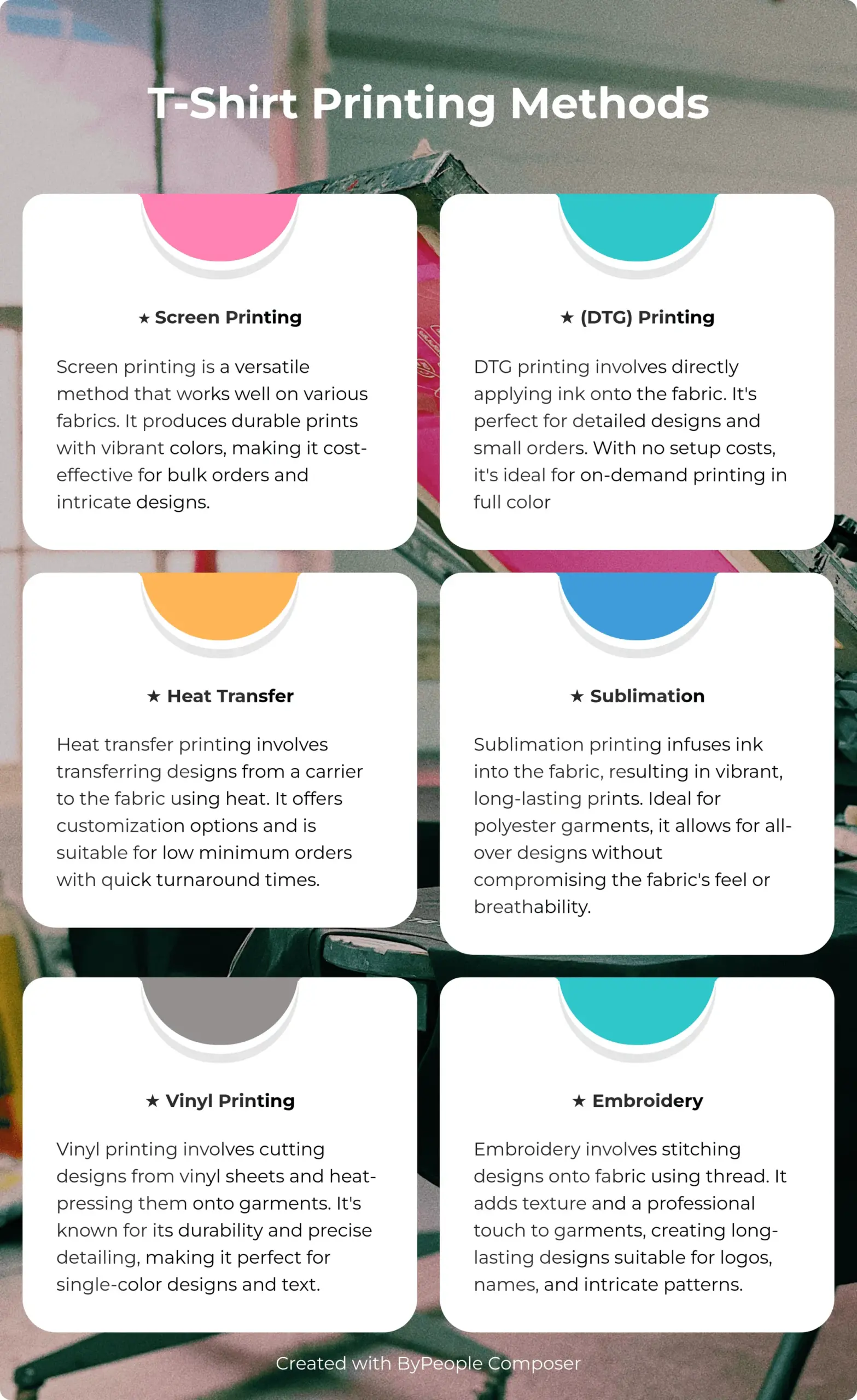

T-Shirt Printing Methods

To ensure that your t-shirt is printed to perfection, you first need to know the most commonly used methods to do so. This way, by understanding how they work, you will be able to make your design work from the get-go, depending on the method you choose.

The most popular methods are screen printing, direct-to-garment or DTG printing, and heat transfer printing. Each has its own set of pros and cons, so let’s explore them one by one.

Screen Printing

Screen printing involves transferring a stenciled design onto a flat surface using a mesh screen, ink and a squeegee. The basic method involves creating a stencil on a fine mesh screen and then pushing ink through to create an imprint of your design on the surface beneath.

This method is a good option for larger orders, as it generally has a lower per-shirt price while maintaining a great intensity of colors. However, it can be more time-consuming and has a much higher initial setup cost than other methods, making it not so suitable for producing a few units.

Also, screen printing holds 56% of the custom t-shirt printing segment (Grand View Research, 2023) Notifying that it is one of the most economical and effective practices in the market, facilitating productions and streamlining processes.

Direct to Garment (DTG)

Direct-to-garment (DTG) digital printing uses a specialized fabric printer — a bit like an inkjet computer printer — to transfer an image directly onto a textile. Because it uses a computerized image rather than a stencil, it’s excellent for producing photographic or highly detailed designs.

DTG printing is a good option for smaller orders, as there is no setup required and the print quality is generally very high. However, DTG printers can be expensive to purchase or rent, and the per-shirt cost can be higher than other methods.

Also, its important to know that digital printing can reduce water consumption by 90% per meter of printed fabric compared to other production methods. This means that you can have an excelent quality t-shirt and also beign helping the planet.

In addition to reduced water consumption, digital printing can decrease energy use by about 37% and lower CO2 emissions by approximately 25%. Overall, digital printing is expected to lower the environmental impact of custom t-shirt printing by using less water, energy, and chemicals than other printing techniques. (Grand Review Research, 2023)

Heat Transfer Printing

Heat transfer printing uses the process of high pressure and heat to transfer an image created in wax to an object or garment.

It is an easy and affordable option that, when used correctly, produces good-quality results since images are durable, heat resistant, adhesive and water resistant. Although the design must be printed on special transfer paper, which adds an extra step to the process and requires specialized machinery, it’s still a pretty good option and a widely used one when customizing your own garments.

Ultimately, the best t-shirt printing method will depend on your specific needs, production quantity and budget. With a bit of research and experimentation, you will find the method that works best for your project. Here you have a poster that will help you in short words to understand this methods.

Recommended T-Shirt Fabrics for Different Printing Methods

Another factor to consider to get the best result on your printed t-shirt is to choose the proper printing method according to the fabric you’ll use. This will make your design look as cool as possible, just the way you want it.

- For screen printing, you’ll want to look for t-shirts made from cotton since they absorb color well and are comfortable to wear, making them perfect along with other plant-based natural fabrics, such as hemp and linen. Other options are the ones that feature a blend of natural and synthetic fibers. 100% synthetic fibers are not encouraged because they don’t absorb color as well and many of these are so stretchy that sometimes special inks need to be used.

- DTG printing is recommended for complex designs, with sharp details and multiple color variations. DTG printers use water-based inks; hence best results occur with natural fabrics, as they tend to absorb liquids. The most suitable textiles for DTG printing are cotton (organic or combed), linen and synthetic blends.

- Heat transfer printing is perfect for any type of t-shirt fabric, in every color, including cotton, polyester tees, caps, etc. It uses pigment ink and transfer paper during the printing process, so it will adhere well to all types of fabrics.

Software and Hardware Used for T-Shirt Design and Printing

There are a few different software options that you can use for t-shirt design and printing. For design, some popular software options include Adobe Illustrator, Inkscape and Adobe Photoshop.

These vector-based programs allow you to create high-quality designs from scratch or customize existing vector designs without damaging the design’s pixel quality, while also allowing you to work with non-vector image formats such as PNG which can’t be modified directly, but can be worked with albeit to a somewhat more limited degree.

If you’ve never used either one of these, make sure to check out this article about the differences between vector and bitmap images and how to optimize images in 2022 for Web Vitals.

Now, if you are deeply interested in production and would like to have your own printing presses, you’ll need a t-shirt printer or an all-in-one machine that can print t-shirts as well as other fabric items. The most popular t-shirt printing hardware options include heat presses, direct-to-garment printers (DTG), and screen printing machines.

T-Shirt Design Practices for Printing

There are small but significant things to keep in mind when it comes to designing for printing purposes, such as source file resolution, design size, and color mode.

First you’ll want to look into your source file resolution. It is essential that your source file is exported in a high enough resolution to ensure that your print will not appear blurry. Although we had already touched on this topic at the beginning of this article, let’s go into more detail on how adjust the resolution in the two most commonly used programs, Adobe Illustrator and Adobe Photoshop.

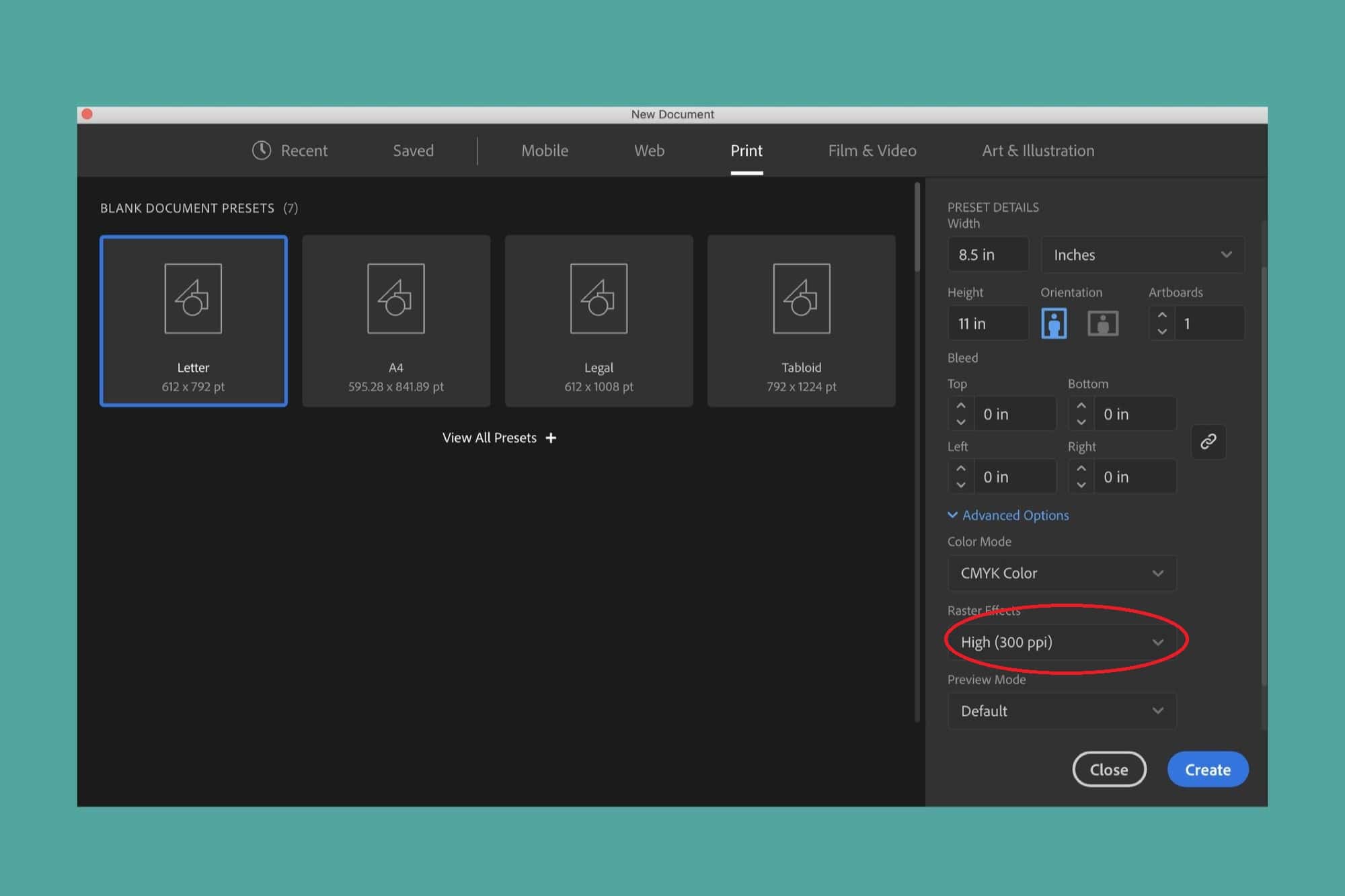

As mentioned above, proper resolution for printing means working with files set between 180-300 dpi, and setting this up in the program you use is very simple. For Adobe Illustrator, when you create the file you will work on, the following menu will pop up, and under “raster effects” choose the high option (300ppi). This way, you will be working on the file in a high resolution.

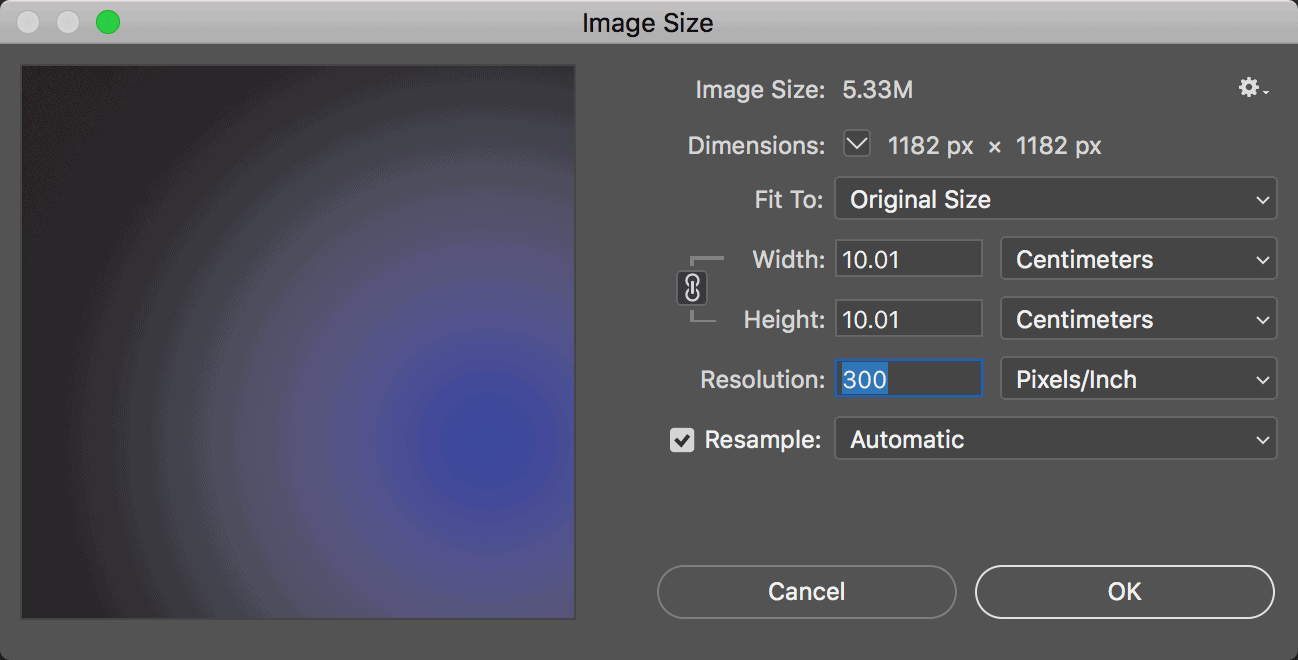

For Adobe Photoshop, open the file in the program as usual. Once opened, click on the Image window, then Image Size, and the following menu will open. It’s important that before changing the resolution value, you uncheck the Resample box, and you’re done!

Second, be sure to size your design appropriately. When choosing the canvas size for your design, it’s best to err on the side of making your design too big rather than too small. Before printing a design it is always safer to scale them down rather than scaling them up, especially if your design is a pixel-based image. This will help ensure that your design looks as intended when printed.

Sizing down is always safer and easier than sizing up, especially if your design is a pixel-based image.

Finally, make sure to use the correct color mode for t-shirt printing. In case you didn’t know (and if you did, it’s always good to get a reminder), there are two color modes in design. RGB is used for digital purposes, while CMYK is used for printing, so when choosing the color mode in the program, go for CMYK as it will produce the most accurate colors in the final product.

Following these guidelines will help you create t-shirt designs that look great and print correctly. With a bit of practice, you’ll be a pro in no time. What you can do while you get the hang of it is use one of our print-ready Vector T-Shirt Designs Bundle, this way, all you have to do is choose your favorite and get onto printing completely stress-free.

Contrast and Color Combination

When it comes to design, a general rule to get great designs that catch the eye is to generate a good contrast when combining colors. This is because t-shirt designs that are not well-contrasted or lack color variety will not pop and may even be unreadable.

You already know which printing methods generate the most vibrant colors (if you don’t remember, revisit that section), so you don’t have to worry about that. Instead, think about what colors to use in the design stage to have an eye-catching image.

For this, the best and easiest tip we have for you is to use the color wheel to your advantage. In the following image, you can see how to generate harmonies or color schemes that, from the theory, work perfectly together. BTW, the colors marked are only examples and will work with any color to which you want to apply the scheme.

Another way to make your design stand out is to experiment with colors and design techniques. Don’t be afraid to try out something new! For example, this amazing Watercolor Design Toolkit has over 480 templates, patterns, brushes and more to create original artwork.

Finally, when creating t-shirt designs, it’s important to consider things like text color and size to create designs that stand out and are easy to read. Whether you’re working with bold, bright colors or muted pastels, a good t-shirt design will always have contrast and variety in color.

Design Placement and Size

This is another aspect to take into account, and maybe one of the most important. Depending on the design, T-shirts that are not placed or sized correctly will probably not look good and may even be unreadable. You need to consider this when deciding on placement and size: the design itself, t-shirt size and t-shirt printer or all-in-one machine.

For t-shirt designs, keep in mind the image resolution and text size when deciding the size and place of the design. This is making sure that the image won’t be pixelated (the same principle we saw above regarding file resolution applies here) and that the text is big enough to be readable. You can also try out different fonts that fit the design style and at the same time are legible, for this we have many options of creative and eye-catching fonts.

For t-shirt size, it’s essential to look into the dimensions of the garment you’ll be customizing. This means avoiding any areas that don’t hold enough space for the final design, so if you want to print a detailed and intricate design, it’s best to choose a size with enough space to hold it and place it in a large area of the t-shirt.

As for t-shirt printers or all-in-one machines, the type of machine you use will also affect design placement and size. For example, some printers have restrictions on where to place designs, depending on the required machinery, which also applies to the size. For example, DTG printers generally have smaller print areas than screen printing machines, so you’ll get a smaller printed area.

Mockups are your best option to ensure that your t-shirt looks great when printed without spending money on production. In this Bulk Mockup Tool for Photoshop Pack we have for you, you will not only find options for different garment types but also access to technological device templates that you may need ahead.

T-Shirt Printing End-to-End Considerations

We’ve already touched on many important points for printing your own t-shirts; now it’s time to go over the last considerations to make your printing and customization experience the best possible.

- We already talked about fabrics, but it doesn’t hurt to bring it up again, better safe than sorry! Different fabrics will absorb ink differently, so it’s essential to consider this to ensure your design turns out how you want it to.

- If you’re using multiple colors in your design and decide to go for screen printing, make sure to use a color separator tool. This will help ensure that each color is printed evenly and correctly.

- When printing, use a high-quality setting on your printer. This will help prevent smudging or bleeding of the ink.

- Ironing your t-shirt after printing can help set the ink and prevent it from fading or bleeding over time. Remember: don’t do it directly on the garment, place a cloth between the newly printed shirt and the iron.

- Test the design before printing on a large, commercial scale. Either print the design onto a smaller piece of fabric or use transfer paper to print out a small version of the design onto a blank t-shirt to identify any potential issues, such as bleeding or smudging, and make any necessary adjustments before printing on a larger scale.

- Follow any care instructions included with the transfer paper or the t-shirt itself. This might consist of washing your shirt on a gentle cycle, using a mild detergent, and avoiding harsh chemicals or fabric softeners when cleaning or caring for your shirt.

Printing your own t-shirt designs can be a fun and rewarding experience, so be sure to have fun with it. Experiment with different design ideas, like our abstract shapes and patterns collection, with hundreds of designs that you can add to your collection of design elements. Or try out new printing techniques and don’t be afraid to make mistakes; after all, the best way to learn and improve is by getting out there and trying new things!

The thing is that the t-shirt market is growing and that is because it has been impacted by: the advancement of digital printing technologies, the popularity of ecommerce, and the desire for unique items among consumers. Personalized options also offer a competitive edge for businesses, as they can boost customer loyalty, increase brand awareness, and generate word-of-mouth referrals. (Printful 2023)

This can be an option for starting your own bussisness or try to have a new hobbit. Well, as Giorgio Armani says, T-shirts are the Alpha and Omega of fashion, which means they are the foundation and complement of any wardrobe. This alludes to the relevance that a T-shirt will always have and the impact it carries. Using exclusive designs and making a good impression with a T-shirt makes a difference and takes you to another level.

Promote with Us

Finally, when it comes to t-shirt design and printing, the possibilities are endless, and the best place for you to find options that are sure to impress your customers is our T-Shirt Designs collection, a directory of curated t-shirt design packs brought to you by our team at unbeatable prices!

The wide variety of designs means you’re guaranteed to find the ideal design styles to meet your business needs. Whether you’re looking to print t-shirts for a business, an event, or just for fun, we’ve got everything you need to get great results. So look no further and explore our T-Shirt Designs to find the perfect t-shirt design for your next project!

Juan Pablo Sarmiento

System engineer from the National University of Colombia, with special interest over entrepreneurship, marketing, productivity and well-being.

Several projects and startups launched in over 20 years of experience.

Best Seller Deals

Check out time-limited deals on software and designs packs